Warehouse automation – a field in continuous development

Automated processes in warehouses and production plants are constantly evolving, delivering both economic and ergonomic benefits. Reducing or eliminating errors is another key objective. Vertical storage lifts, XYZ movements, telescoping toolboxes are some examples of applications.

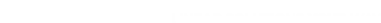

By combining a QME linear unit with a vision camera, you can automatically position the unit according to, for example, the size of the material being handled. Similar functionality can be found in e-commerce flows where postal packages are to be sorted by address label, weight or height.

A flexible and ergonomic solution such as shelves with pull-out drawers, makes tasks like warehouse picking easier. Telescopic rails are available with stroke lengths of over two meters and can utilize the entire depth of the shelf.

What exactly is a vision camera? And what role can it play in an automated warehouse? Our video clip illustrates an example with a vision camera, a linear unit and a belt conveyor.

Our sales manager shares details about an exciting project with a three-axis system of linear units for an industrial saw machine, where material is processed while it remains in motion. We also demonstrate our pick & place machine, consisting of a belt-driven linear unit CTJ, and two ball screw-driven linear units CTV.

A planetary gearbox is an excellent complement to a linear unit. But why do you need a planetary gearbox? Our application engineer Pontus explains. He also explains the differences between a belt-driven and a ball screw-driven linear unit.

If you need to pull, push or lift objects, actuators can be a suitable solution. Electromechanical actuators require little maintenance, are energy efficient and reduce the risk of downtime. Our candy box machine shows an example of a pick & place application.

See our candy box machine in action

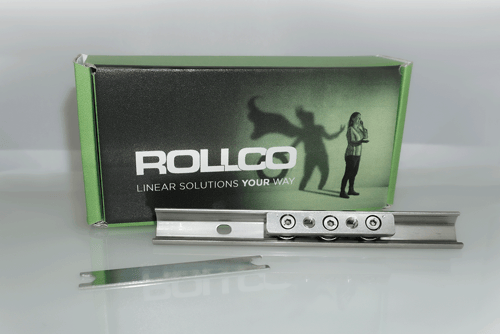

Order our demo kit with rail and slider with rollers and see how C-Rail looks and works. The C-Rail is a relatively simple product, which can solve advanced applications and is also a cost-effective solution. The system is available in both stainless and galvanized steel, which makes it well suited for some demanding environments.

CONTENT

- Streamline warehouse flow with smart linear units

- Space-saving solution in storage systems

- Warehouse automation with vision camera and linear units

- Multi-axis systems of linear units

- The planetary gear – a partner to your linear unit

- Linear actuators for more efficient material handling

Order a sample kit